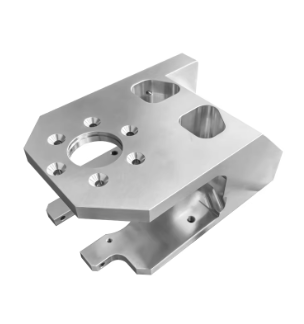

aluminium parts manufacturer

An aluminum parts manufacturer stands as a cornerstone in modern industrial production, specializing in the design, development, and fabrication of precision aluminum components. These facilities combine state-of-the-art CNC machining technology, advanced casting processes, and innovative engineering solutions to create high-quality aluminum parts for diverse applications. The manufacturing process encompasses multiple specialized techniques, including die casting, extrusion, and precision machining, all orchestrated within a controlled environment to ensure optimal quality and consistency. These manufacturers employ sophisticated quality control systems, utilizing advanced measurement and testing equipment to maintain strict adherence to international standards and specifications. Their capabilities extend to producing both standard and custom aluminum components, ranging from simple brackets to complex aerospace parts. The facility's expertise includes working with various aluminum alloys, each selected for specific applications based on required strength, weight, and durability characteristics. Modern aluminum parts manufacturers also integrate sustainable practices, implementing efficient material usage and recycling programs to minimize environmental impact while maximizing resource utilization. Their comprehensive services often include design assistance, prototype development, and full-scale production, supported by experienced engineering teams who can optimize designs for manufacturability and cost-effectiveness.