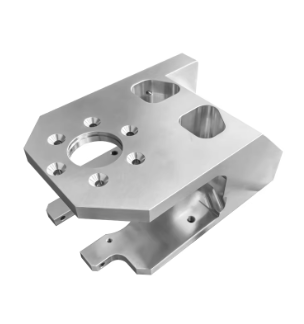

cnc parts and supplies manufacturer

A CNC parts and supplies manufacturer represents a cutting-edge industrial facility specialized in producing precision-engineered components through computer numerical control technology. These manufacturers utilize advanced machinery and software to create complex parts with exceptional accuracy and consistency. Their operations encompass a wide range of services, from prototyping to large-scale production, employing state-of-the-art CNC machines including mills, lathes, and multi-axis systems. These facilities maintain strict quality control measures while offering comprehensive solutions for various industries such as aerospace, automotive, medical devices, and electronics. The manufacturing process involves converting digital designs into physical components through automated machining processes, ensuring precise tolerances and superior finish quality. Modern CNC manufacturers integrate CAD/CAM software with advanced machinery to optimize production efficiency and maintain consistent quality standards. They typically offer additional services such as material sourcing, quality inspection, and custom finishing operations. The facility's capabilities extend to working with diverse materials including metals, plastics, and composites, providing clients with flexible manufacturing solutions tailored to their specific requirements.