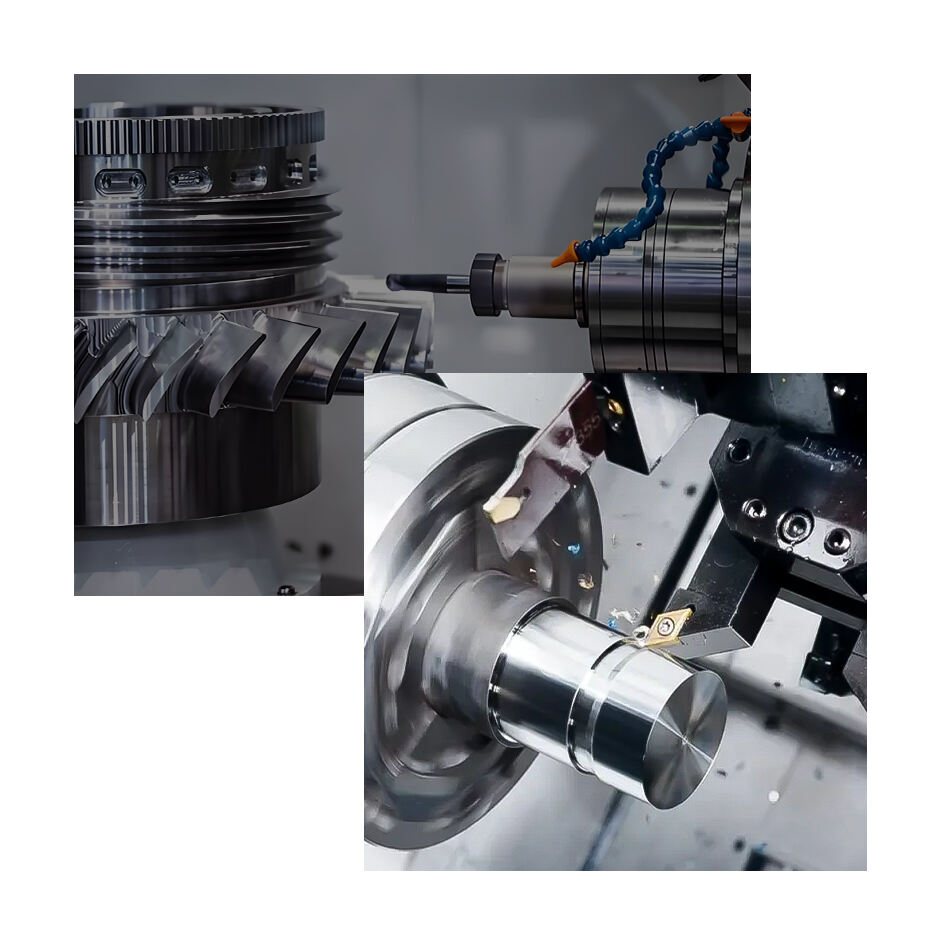

high precision machining part

High precision machining parts represent the pinnacle of manufacturing excellence, combining advanced technology with meticulous engineering processes to create components with exceptional accuracy and reliability. These parts are manufactured using state-of-the-art CNC machines and sophisticated quality control systems, ensuring dimensional accuracies down to micrometers. The manufacturing process involves complex multi-axis machining operations, temperature-controlled environments, and advanced measurement systems to maintain consistent quality. These components are essential in various industries, including aerospace, medical equipment, automotive, and precision instruments. The parts undergo rigorous quality control processes, including dimensional inspection, surface finish analysis, and material composition verification. With capabilities to handle various materials from aerospace-grade aluminum to specialized alloys, high precision machining parts meet strict industry standards and specifications. The combination of advanced manufacturing techniques, precise tooling, and expert craftsmanship ensures these components deliver optimal performance in critical applications where accuracy and reliability are paramount.