Grundlagen moderner CNC-Bearbeitungsverfahren und ihrer einzigartigen Fähigkeiten

CNC-Bearbeitung hat die Fertigungsindustrie revolutioniert, indem es eine beispiellose Präzision, Konsistenz und Effizienz bei der Herstellung komplexer Bauteile bietet. Mit dem technologischen Fortschritt haben sich verschiedene CNC-Bearbeitungsverfahren weiterentwickelt, um unterschiedliche Produktionsanforderungen zu erfüllen. Jede Technik bringt ihre eigenen Vorteile und spezifischen Anwendungen mit sich, weshalb es entscheidend ist, dass Hersteller und Konstrukteure ihre Unterschiede verstehen. Dieser umfassende Leitfaden erläutert die grundlegenden Unterschiede zwischen Drehen, Fräsen, 5-Achs-Bearbeitung und Drahtschnitt, um Ihnen bei fundierten Entscheidungen für Ihre Fertigungsprojekte zu helfen.

CNC-Drehen: Die Kunst der Rotationssymmetrie

Grundprinzipien der CNC-Drehoperationen

Die CNC-Drehbearbeitung stellt einen der grundlegendsten Prozesse in der modernen Fertigung dar. Bei diesem Verfahren dreht sich das Werkstück, während ein Schneidwerkzeug Material abträgt, um zylindrische Teile herzustellen. Das Verfahren eignet sich hervorragend zur Herstellung von rotationssymmetrischen Bauteilen wie Wellen, Stiften und anderen zylindrischen Objekten. Dabei bleibt das Schneidwerkzeug relativ stationär, während das Material mit hohen Drehzahlen rotiert, was eine präzise Durchmesserkontrolle und eine hervorragende Oberflächenqualität ermöglicht.

Der Drehprozess erfolgt typischerweise an einer Drehmaschine mit zwei Hauptbewegungsachsen – der X- und der Z-Achse. Diese Konfiguration ermöglicht es dem Schneidwerkzeug, entlang der Länge des Werkstücks sowie auf dessen Mittelpunkt zu oder von ihm weg zu bewegen, wodurch verschiedene Profile, Gewinde und Merkmale erzeugt werden können. Moderne CNC-Drehzentren können zusätzliche Achsen und angetriebene Werkzeuge integrieren, wodurch ihre Vielseitigkeit über einfache zylindrische Formen hinausgeht.

Anwendungen und Vorteile des Drehens

Die CNC-Drehbearbeitung wird in Branchen, die präzise zylindrische Komponenten erfordern, umfassend eingesetzt. Automobilhersteller nutzen das Drehen zur Herstellung von Motorkomponenten, während Luft- und Raumfahrtunternehmen es für die Fertigung von Turbinenteilen verwenden. Das Verfahren bietet außergewöhnliche Genauigkeit bei der Durchmesserkontrolle und eignet sich daher ideal für Teile, die exakt in Baugruppen passen müssen.

Einer der Hauptvorteile der CNC-Drehbearbeitung ist die Fähigkeit, enge Toleranzen einzuhalten, während Teile schnell hergestellt werden. Die kontinuierliche Schneidbewegung führt zu höheren Materialabtragraten im Vergleich zu anderen Verfahren, insbesondere bei zylindrischen Komponenten. Zudem können moderne Drehzentren mehrere Bearbeitungsschritte in einer einzigen Aufspannung durchführen, wodurch die Produktionszeit verkürzt und die Genauigkeit verbessert wird.

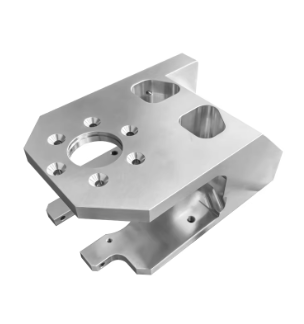

CNC-Fräsen: Vielseitiger Materialabtrag

Grundlegende Aspekte von Fräsoperationen

Die CNC-Fräsung stellt ein vielseitiges Bearbeitungsverfahren dar, bei dem rotierende Schneidwerkzeuge Material von einem stationären Werkstück entfernen. Im Gegensatz zur Drehbearbeitung eignet sich das Fräsen hervorragend zur Herstellung komplexer geometrischer Merkmale, ebener Oberflächen und verwickelter Muster. Der Prozess umfasst typischerweise drei oder mehr Bewegungsachsen, wodurch sich das Schneidwerkzeug in verschiedene Richtungen relativ zum Werkstück bewegen kann.

Moderne Fräsmaschinen verwenden hochentwickelte Computersteuerungen, um die Werkzeugbewegungen zu koordinieren, wodurch die Erstellung komplexer 3D-Formen ermöglicht wird. Das Verfahren kann eine breite Palette von Materialien verarbeiten, von weichen Kunststoffen bis hin zu gehärteten Stählen, und ist daher in verschiedenen Fertigungssektoren unverzichtbar.

Erweiterte Fräsfähigkeiten

Heutige CNC-Fräscenter verfügen über fortschrittliche Funktionen wie automatische Werkzeugwechsler, Tastsysteme und Hochgeschwindigkeitsspindeln. Diese Fähigkeiten ermöglichen die kontinuierliche Bearbeitung komplexer Teile mit minimalem manuellem Eingriff. Die Flexibilität des Fräsens erlaubt die Erzeugung von Nuten, Taschen, Konturen und anderen Geometrien, die mit Drehen allein schwer oder gar nicht realisierbar wären.

Die Möglichkeit, mehrere Operationen in einer einzigen Aufspannung durchzuführen, verkürzt die Produktionszeit und verbessert die Genauigkeit. Moderne Fräsmaschinen können zudem in CAD/CAM-Systeme integriert werden, wodurch eine nahtlose Umsetzung digitaler Konstruktionen in fertige Bauteile möglich wird.

5-Achs-CNC-Bearbeitung: Ultimative Flexibilität

Revolutionäre Fähigkeiten von 5-Achs-Systemen

die 5-Achs-CNC-Bearbeitung stellt die Spitze der Bearbeitungstechnologie dar und bietet beispiellose Flexibilität bei der Teilefertigung. Dieses fortschrittliche Verfahren ergänzt die traditionellen drei linearen Achsen um zwei rotierende Achsen, wodurch das Schneidwerkzeug das Werkstück praktisch aus jedem Winkel bearbeiten kann. Diese Fähigkeit reduziert den Bedarf an mehreren Aufspannungen erheblich und ermöglicht die Herstellung komplexer Geometrien in einem einzigen Arbeitsgang.

Die zusätzlichen Bewegungsachsen ermöglichen einen besseren Werkzeugzugang zu Hinterschnitten und komplexen Konturen. Diese verbesserte Zugänglichkeit führt zu einer höheren Oberflächenqualität und verkürzten Bearbeitungszeiten bei komplexen Bauteilen. Das Verfahren eignet sich hervorragend zur Herstellung von Luft- und Raumfahrtkomponenten, medizinischen Geräten und anderen hochpräzisen Teilen mit komplizierten Geometrien.

Anwendungen und Vorteile der 5-Achs-Bearbeitung

Branchen, die komplexe Bauteile mit engen Toleranzen benötigen, profitieren besonders von der 5-Achs-CNC-Bearbeitung. Der Luft- und Raumfahrtsektor nutzt diese Technologie zur Herstellung von Turbinenschaufeln, während Hersteller medizinischer Geräte aufwendige Implantate und chirurgische Instrumente fertigen. Die Fähigkeit, komplexe Formen in einer einzigen Aufspannung zu bearbeiten, reduziert die Handhabungszeit und verbessert die Gesamtgenauigkeit.

Die erhöhte Effizienz der 5-Achsen-Bearbeitung führt oft zu kürzeren Produktionszeiten und besseren Oberflächenqualitäten im Vergleich zu herkömmlichen 3-Achsen-Verfahren. Obwohl die anfänglichen Investitionskosten für 5-Achsen-Anlagen höher sind, können die verbesserten Fähigkeiten und verkürzten Rüstzeiten bei der Produktion hochkomplexer Teile zu erheblichen Kosteneinsparungen führen.

Draht-EDM-Schneiden: Präzision durch elektrische Entladung

Grundlagen der Draht-EDM-Technologie

Der Drahtfunkenerosionsverfahren (EDM) stellt eine spezialisierte Form der CNC-Bearbeitung dar, bei der elektrische Energie zum Schneiden leitfähiger Materialien verwendet wird. Im Gegensatz zu herkömmlichen Schneidverfahren setzt das Draht-EDM eine dünne Drahtelektrode ein, die das Werkstück niemals physisch berührt. Stattdessen erzeugen elektrische Entladungen zwischen dem Draht und dem Material einen kontrollierten Abtragungsprozess, der präzise Schnitte ermöglicht.

Das Verfahren zeichnet sich durch die Herstellung komplexer Formen in gehärteten Materialien aus, die mit konventionellen Methoden schwer zu bearbeiten wären. Der Drahtdurchmesser liegt typischerweise zwischen 0,10 mm und 0,30 mm, was äußerst präzise Schnitte und feine Details ermöglicht.

Spezialanwendungen des Draht-EDM

Draht-EDM findet breite Anwendung in der Werkzeug- und Formenherstellung, wo Präzision und die Fähigkeit, gehärtete Materialien zu schneiden, entscheidend sind. Das Verfahren kann komplexe Formen mit engen Toleranzen erzeugen und eignet sich daher hervorragend für die Herstellung von Stanz- und Matrizenbauteilen, Strangpressformen sowie Präzisionsteilen für verschiedene Industrien.

Die berührungslose Drahterosion eliminiert Schnittkräfte und ermöglicht so die verzugsfreie Bearbeitung empfindlicher oder dünnwandiger Bauteile. Diese Eigenschaft macht sie besonders wertvoll für die Herstellung von Medizingeräten, Luft- und Raumfahrtkomponenten sowie anderen Präzisionsteilen, die höchste Genauigkeit erfordern.

Häufig gestellte Fragen zu CNC-Bearbeitungsverfahren

Welches CNC-Bearbeitungsverfahren bietet die beste Oberflächenqualität?

Jedes CNC-Bearbeitungsverfahren kann bei richtiger Optimierung hervorragende Oberflächenqualitäten erreichen. Das Drehen liefert typischerweise die beste Oberflächenqualität bei zylindrischen Teilen, während das 5-Achs-Fräsen bei komplexen Oberflächen überzeugt. Mit dem Drahterodieren können besonders feine Oberflächen auf ebenen Flächen und Durchbrüchen erzielt werden, insbesondere bei mehrfachen Nachbearbeitungsdurchgängen.

Wie wähle ich zwischen verschiedenen CNC-Bearbeitungsverfahren für mein Projekt?

Die Wahl hängt von mehreren Faktoren ab, einschließlich der Geometrie des Teils, dem Material, den Toleranzanforderungen und dem Produktionsvolumen. Drehen eignet sich ideal für zylindrische Teile, Fräsen für komplexe 3D-Formen, 5-Achs-Bearbeitung für Teile, die Ansätze aus mehreren Winkeln erfordern, und Draht-EDM für präzise Schnitte in gehärteten Materialien oder komplexen Profilen.

Welche Materialien können mit diesen CNC-Bearbeitungsmethoden verarbeitet werden?

Die meisten CNC-Bearbeitungsverfahren können eine breite Palette an Materialien verarbeiten. Drehen und Fräsen funktionieren gut mit Metallen, Kunststoffen und Verbundwerkstoffen. Die 5-Achs-Bearbeitung eignet sich besonders für schwer bearbeitbare Materialien wie Titan und Inconel. Draht-EDM ist auf elektrisch leitfähige Materialien beschränkt, überzeugt aber bei der Bearbeitung von gehärteten Stählen und anderen harten Metallen.

Ist die 5-Achs-Bearbeitung immer besser als das 3-Achsen-Fräsen?

Obwohl die 5-Achs-Bearbeitung größere Flexibilität und Leistungsfähigkeit bietet, ist sie nicht immer die beste Wahl. Einfache Teile können wirtschaftlicher mit einer 3-Achsen-Fräsung hergestellt werden. Die 5-Achsen-Bearbeitung wird vorteilhaft, wenn komplexe Geometrien, Teile, die mehrere Aufspannungen erfordern, oder eine hervorragende Oberflächenqualität auf komplexen Flächen benötigt werden.

Inhaltsverzeichnis

- Grundlagen moderner CNC-Bearbeitungsverfahren und ihrer einzigartigen Fähigkeiten

- CNC-Drehen: Die Kunst der Rotationssymmetrie

- CNC-Fräsen: Vielseitiger Materialabtrag

- 5-Achs-CNC-Bearbeitung: Ultimative Flexibilität

- Draht-EDM-Schneiden: Präzision durch elektrische Entladung

- Häufig gestellte Fragen zu CNC-Bearbeitungsverfahren