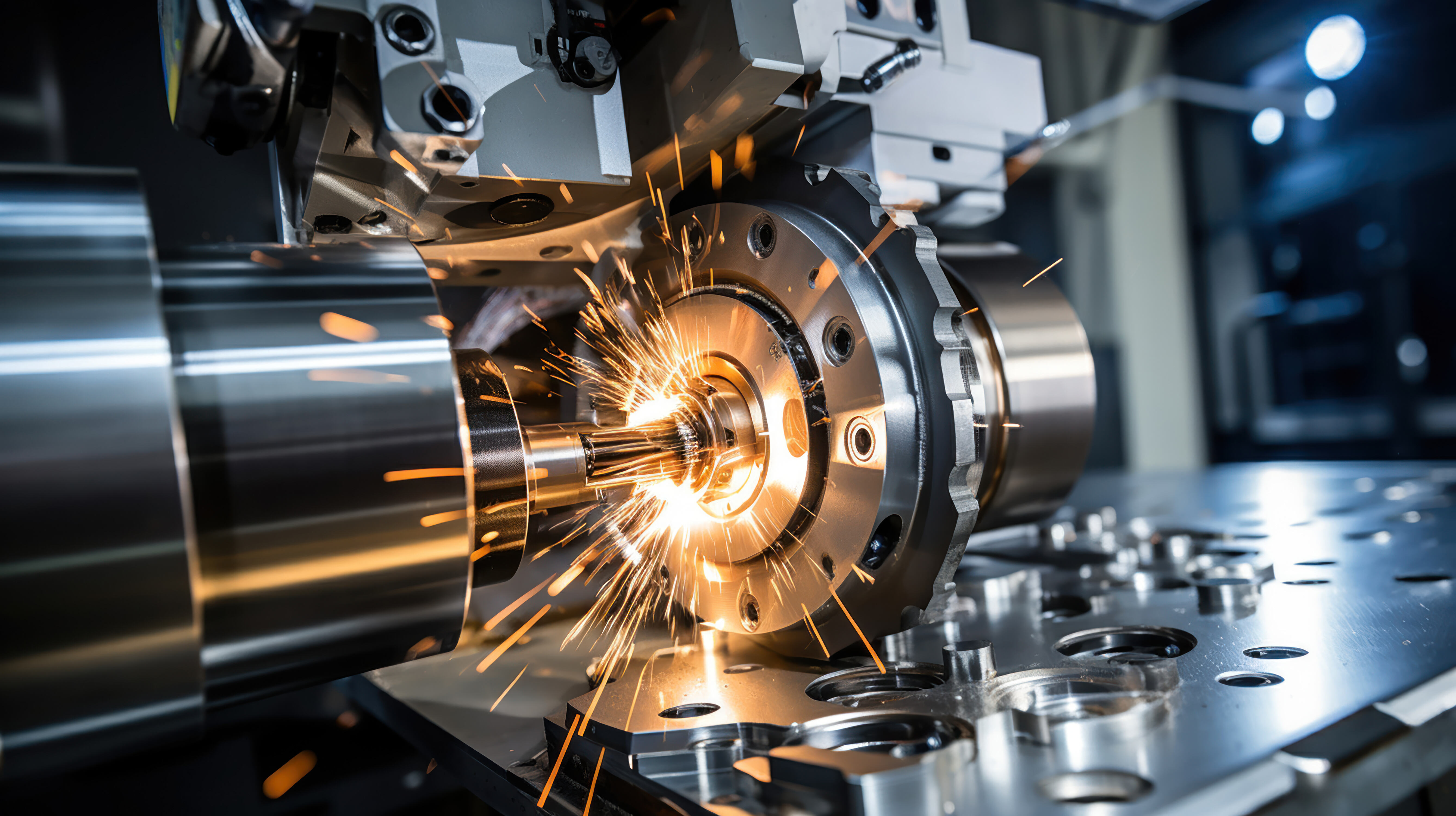

Fattori Chiave nella Valutazione della Qualità della Fresatura CNC

Tolleranze Dimensionali e Coerenza Geometrica

In Componenti di precisione per fresatura CNC , le tolleranze dimensionali sono davvero importanti perché determinano quanto efficacemente la parte finita funzionerà quando viene assemblata. Conoscere queste tolleranze, che sono tipicamente nell'ordine dei micrometri, ci permette di essere precisi in ogni particolare lavorato. Le parti fresate con CNC sono geometricamente consistenti, e ciò viene verificato con l'ausilio di calibri e comparatori per garantire che siano conformi al progetto. Questa precisione fa sì che le parti si assemblino correttamente. L'applicazione di standard industriali come ISO 2768.5 fornisce istruzioni dettagliate sui test e sulla registrazione di tali tolleranze per una produzione di alta qualità.

Requisiti di Finitura Superficiale e Protocolli di Misurazione

La finitura superficiale è fondamentale per le proprietà estetiche, funzionali e di attrito dei componenti CNC. Parametri come Ra o Rz permettono di determinare valori ottimali per applicazioni specifiche e, di conseguenza, ottimizzare le prestazioni e l'aspetto del prodotto. Siamo in grado di misurare la rugosità e la qualità della superficie utilizzando profilometri, verificando il rispetto delle specifiche tecniche. Studi ed esperti del settore hanno dimostrato che la durata nel tempo delle parti dipende da una corretta finitura superficiale. Questo tipo di integrità garantisce che i componenti realizzati con macchine CNC resistano a qualsiasi tipo di usura e agli agenti atmosferici, mantenendo inalterata la loro resistenza.

Integrità dei Materiali & Analisi Microstrutturale

L'integrità del materiale viene analizzata attraverso la microstruttura della dimensione dei grani e la distribuzione delle fasi, che influenzano le proprietà meccaniche. Procedure come la metallografia e la diffrazione a raggi X sono utili per individuare dati affidabili e incompleti grazie al rilevamento dei difetti, ai fini della valutazione della qualità. Il codice confronta le scoperte e le prestazioni con ricerche che mostrano la relazione tra la struttura dei grani del pezzo e le sue caratteristiche di prestazione, come resistenza a trazione e resistenza alla fatica – queste ultime due influenzano la robustezza/durabilità e l'affidabilità dei componenti lavorati al CNC. Questo tipo di test, spesso chiamato test di perdita d'aria, garantisce che i prodotti soddisfino elevati standard qualitativi prima di essere immessi sul mercato.

Selezione dei Materiali per Componenti di Precisione

Compatibilità con i Processi di Lavorazione

La scelta del materiale appropriato per la lavorazione CNC è fondamentale, poiché influisce direttamente sulla lavorabilità e sulla qualità delle parti prodotte. Materiali più facili da lavorare, come l'alluminio, tendono ad essere processati più rapidamente e a costi inferiori rispetto alle leghe più dure (ad esempio titanio o Inconel), che possono richiedere utensili di taglio costosi. Quando scelgo i materiali, valuto la resistenza, il peso e il costo del materiale. Per esempio, l'acciaio inossidabile può offrire una buona resistenza e resistenza alla corrosione, ma potrebbe essere più pesante e costoso rispetto ai polimeri. I materiali comunemente utilizzati per le precisioni meccaniche CNC includono tra gli altri acciaio inossidabile, titanio e diversi tipi di polimeri; ma oltre alle loro proprietà fisiche e chimiche, la lavorazione è Q2: Quali tipi di materiale la vostra azienda può reperire? A: Abbiamo fornitori con cui collaboriamo da tempo per reperire acciaio inossidabile, titanio e alcuni materiali speciali, se richiesti dal cliente. Sono stati selezionati in modo da trovare un equilibrio tra questi fattori al fine di soddisfare progetti specifici.

Stabilità Termica e Resistenza all'Usura

La stabilità termica di un materiale svolge un ruolo fondamentale nelle sue prestazioni durante le operazioni di lavorazione. Articoli che subiscono variazioni dimensionali a temperature elevate causano un'inefficienza e una mancanza di precisione dello strumento. In particolare, l'utilizzo di materiali con elevata stabilità termica, come l'acciaio temprato, garantisce che la precisione venga mantenuta anche durante operazioni di lavorazione estreme. La resistenza all'usura è altrettanto importante, poiché può influenzare la durata dello strumento e del componente; per questo motivo materiali come il carburo vengono utilizzati per gli utensili da taglio. Lo standard industriale dimostra che scegliere materiali con elevata durezza e resistenza all'usura rappresenta la scelta migliore per applicazioni industriali che richiedono una finitura molto fine ed eccellenti proprietà di lucidatura. Questo approccio assicura una lunga vita ai componenti che produco.

Normative Specifiche per il Settore

Quando si scelgono i materiali per componenti di precisione realizzati con la tornitura CNC, è molto importante considerare anche le normative e i requisiti del settore. Nel settore aeronautico vengono applicate direttamente le norme ASTM, mentre in ambito automobilistico si utilizza l'ISO/TS 16949. Il rispetto di queste norme rappresenta un fondamentale aspetto legato alla sicurezza e alle prestazioni, oltre a contribuire alla riduzione del tasso di guasti. I numeri dimostrano che le conseguenze derivanti da inadempienze possono ammontare a milioni di sterline in termini di danni al marchio e multe, motivo per cui è essenziale tenerle in considerazione durante la selezione dei materiali. Dopo la lavorazione dei materiali, è necessario effettuare un rigoroso processo di controllo della qualità e certificazione per assicurarsi che soddisfino le specifiche richieste. In questo modo si può essere certi al 100% che il prodotto finale corrisponda alle specifiche richieste per il tuo cerchio e possa essere utilizzato senza alcun problema. Il risultato è tranquillità e la garanzia di un adattamento perfetto e delle migliori prestazioni.

Tecniche Avanzate di Misurazione per il Controllo Qualità

Applicazioni CMM (Coordinate Measuring Machine)

I MCM sono fondamentali per garantire misurazioni molto precise su geometrie complesse nei componenti meccanici di precisione realizzati mediante macchine CNC, riducendo notevolmente gli errori umani nel processo di ispezione. Le misurazioni dettagliate di componenti complessi portano a una maggiore accuratezza. Esistono diversi tipi di MCM, tra cui MCM a ponte, a mensola e a braccio orizzontale, in grado di soddisfare le diverse esigenze del settore e delle configurazioni produttive. Ad esempio, il tipo a ponte è comunemente utilizzato negli ambienti di produzione di massa poiché questo tipo è stabile. Studi di caso hanno dimostrato che l'implementazione di tecniche con MCM ha permesso di migliorare l'efficienza e ridurre gli errori, confermando la loro importanza per il miglioramento della qualità produttiva e per una produzione pronta all'uso.

Comparatori Ottici e Sistemi di Scansione Laser

Gli comparatori ottici di ispezione sono strumenti fondamentali, conformi a rigorosi standard qualitativi per la valutazione precisa dei profili bidimensionali. Questa tecnica si rivela molto efficace per verificare le dimensioni dei componenti meccanici rispetto ai requisiti di progetto. Al contrario, un sistema di scansione laser offre funzionalità più sofisticate, tra cui la capacità di acquisire in modo preciso e rapido misurazioni tridimensionali. Il controllo qualità è notevolmente migliorato grazie all'integrazione di queste tecnologie. Fonti del settore osservano che, nonostante il costo iniziale superiore, i sistemi di scansione laser possono offrire maggiore precisione, tempi di ciclo più rapidi e, nel complesso, rappresentare una scelta più appropriata nel lungo termine considerando il rapporto costi-benefici, rispetto all'utilizzo dei comparatori ottici in determinate circostanze.

Monitoraggio in Processo con Sensori IoT

L'utilizzo di sensori IoT nelle Parti di Precisione per Macchine CNC permette inoltre il monitoraggio di temperatura, vibrazioni e velocità di avanzamento, consentendo aggiustamenti in tempo reale del processo. Questo flusso continuo di dati è utile anche per la manutenzione preventiva, che può ridurre drasticamente i tempi di fermo e prolungare la vita degli utensili. Nella pratica, i produttori hanno applicato con successo soluzioni IoT, ottenendo un miglioramento nel controllo qualità e dimostrando il valore di queste tecnologie per il settore della lavorazione CNC al fine di mantenere standard elevati. Attraverso l'utilizzo di sensori IoT, le aziende possono ottimizzare le proprie operazioni producendo prodotti di alta qualità in modo più costante, portando a un miglioramento dell'efficienza operativa.

Trattamenti Post-Lavorazione per Migliorare le Prestazioni

Metodi di Lucidatura e Sbavatura di Precisione

Un buon finitura superficiale e la rimozione delle bave rappresentano una fase importante dopo la lavorazione meccanica, in quanto migliorano efficacemente la capacità portante e la sicurezza nell'utilizzo di componenti di precisione per macchine CNC. Per migliorare la qualità superficiale del pezzo e utilizzare minori quantità di materiale, le aziende impiegano macchine per la finitura su larga scala per preparare i componenti in modo uniforme, permettendo al processo di finitura di operare 1. Il tutto con un'elevata qualità superficiale e un'elevata accuratezza dimensionale – per ulteriori dettagli, consultare il nostro glossario. Allo stesso tempo, la sbavatura elimina gli spigoli vivi e le bave, riducendo al minimo il rischio di guasti meccanici e migliorando la sicurezza dell'utente. Ad esempio, dati del settore mostrano che quando si effettuano correttamente le operazioni di sbavatura e lucidatura, si registra una significativa riduzione del numero di reclami da parte dei clienti e di prodotti restituiti; ciò sottolinea ulteriormente l'importanza di tali procedure nel controllo della qualità.

Rivestimenti Protettivi & Indurimento Superficiale

I rivestimenti protettivi e i trattamenti di indurimento superficiale contribuiscono anche alla durata e alla versatilità dei componenti lavorati al CNC. Come è noto nell'arte, i rivestimenti come l'anodizzazione e la verniciatura a polvere sono ben noti per migliorare la resistenza alla corrosione e sono quindi indispensabili per progettare una maggiore durata dei prodotti utilizzati in condizioni severe. I trattamenti di indurimento superficiale (indurimento superficiale, nitridazione) aumentano la resistenza all'usura, incrementando considerevolmente la vita utile dei componenti. Le evidenze derivanti da studi mostrano chiaramente che le parti ricevono effettivamente un miglioramento della durata grazie a questi tipi di trattamenti superficiali, sottolineando l'importanza di tali metodi nel mantenere l'integrità strutturale e la funzionalità dei prodotti lavorati a un livello elevato.

Processi di Trattamento Termico per la Riduzione delle Tensioni

Dopo il taglio, il trattamento termico per la distensione è un passo necessario per rimuovere le tensioni interne prodotte durante la lavorazione, ottenendo così una migliore stabilità dimensionale delle parti. Processi come ricottura e tempra sono importanti per modificare le proprietà meccaniche e migliorare le prestazioni. I TRATTAMENTI TERMICI servono per alleviare le sollecitazioni, garantire stabilità nelle applicazioni di precisione, specialmente quando la INTEGRITÀ DELLE PARTI è un fattore da considerare. Esperti del settore ribadiscono l'importanza di tali trattamenti termici per le prestazioni in applicazioni critiche, sostenendo che questi metodi forniscono integrità strutturale e accuratezza dimensionale richieste in ambienti impegnativi.

Implementazione di Sistemi Continui di Controllo Qualità

Implementazione del Controllo Statistico dei Processi (CSP)

Il controllo statistico dei processi (SPC) è essenziale per regolare la coerenza del processo nel lungo periodo grazie all'analisi continua dei dati, che permette di ottimizzare proattivamente le operazioni e ridurre i margini di controllo. L'SPC si basa su metodi statistici per monitorare e controllare un processo e i suoi prodotti. Nell'implementazione di un programma SPC vi sono diversi passaggi importanti. I primi indicatori chiave di prestazione (KPI) da considerare sono quelli rilevanti per il processo produttivo, e devono essere definiti. In secondo luogo, vengono impostati grafici di controllo per rappresentare graficamente le fluttuazioni e i modelli nel tempo, il che consente di identificare precocemente eventuali problemi. I produttori hanno segnalato un miglioramento della qualità e una riduzione dei costi come risultato dei progetti SPC, dimostrando che questo metodo può migliorare i processi produttivi e la qualità di prodotti e servizi. L'integrazione dell'SPC nei circuiti di controllo qualità può portare a notevoli efficienze e a prodotti di alta qualità per le aziende.

Rilevamento in tempo reale dei difetti mediante intelligenza artificiale

L'importanza dell'intelligenza artificiale (AI) nella rilevazione in tempo reale dei difetti è enorme, poiché migliora significativamente il processo di lavorazione, permettendo interventi rapidi. Le soluzioni di intelligenza artificiale, in particolare quelle che utilizzano algoritmi di machine learning, possono elaborare i dati e rilevare difetti durante tutto il processo produttivo. La precisione nella rilevazione di FV si basa principalmente su dati precedenti che informano l'algoritmo di machine learning; i modelli diventano sempre più precisi e commettono meno errori nella previsione di nodi anomali nella rete. Molte aziende hanno implementato soluzioni basate sull'intelligenza artificiale nei loro sistemi di controllo qualità (QC), ottenendo una crescita tangibile. Ad esempio, alcune aziende hanno registrato una riduzione dei tassi di difetto e una risoluzione più rapida dei potenziali problemi di qualità, con un conseguente aumento della fiducia da parte dei clienti. L'adozione dell'intelligenza artificiale nei sistemi di controllo qualità offre un chiaro vantaggio competitivo, aumentando l'efficienza e la precisione delle operazioni di produzione.

Conformità e procedure di audit ISO 9001

È importante avere una conoscenza delle norme ISO 9001 poiché costituiscono il pilastro fondamentale dei sistemi di gestione della qualità efficaci, utilizzati nelle aziende che producono parti di precisione mediante tornio CNC. Essere conformi alla ISO 9001 significa che un'organizzazione sta rispettando uno standard internazionale di qualità, elemento che favorisce la coerenza nella qualità del prodotto e l'efficienza nei processi. Questo è possibile grazie a strumenti di audit interni ed esterni, che rappresentano la base per garantire il mantenimento della conformità e permettono il miglioramento continuo. Gli audit interni ed esterni consentono alle aziende di esaminare le proprie pratiche individuando aree da migliorare oppure, al contrario, mostrando il livello di conformità raggiunto. Ovviamente, evidenze statistiche hanno dimostrato una relazione diretta tra la certificazione ISO e il miglioramento dell'efficienza nel settore manifatturiero; quindi gli standard ISO 9001 giocano sicuramente un ruolo fondamentale nel garantire eccellenza e affidabilità nell'aspetto produttivo.

Domande frequenti sui componenti di precisione per la lavorazione CNC

Quali sono i principali fattori che influenzano la qualità dei componenti di precisione per la lavorazione CNC?

Diversi fattori chiave influenzano la qualità dei componenti di precisione per la lavorazione CNC, tra cui le tolleranze dimensionali, i requisiti di finitura superficiale, l'integrità del materiale e l'analisi della microstruttura.

Come la scelta del materiale impatta sulla lavorazione CNC?

La scelta del materiale è cruciale poiché influisce sulla lavorabilità, stabilità termica, resistenza all'usura e conformità agli standard del settore, tutti fattori che determinano la qualità e le prestazioni dei componenti lavorati.

Quali sono i vantaggi dell'utilizzo di macchine a misurare tridimensionali (CMM) nella lavorazione CNC?

Le CMM forniscono misurazioni ad alta precisione, riducono al minimo gli errori umani durante le ispezioni e offrono una maggiore accuratezza nella rilevazione delle misure dettagliate di componenti CNC complessi.

Perché la rilevazione in tempo reale dei difetti è importante nella lavorazione CNC?

Il rilevamento in tempo reale dei difetti, in particolare con l'uso dell'intelligenza artificiale, permette di intervenire immediatamente, riducendo così la percentuale di difetti e aumentando la precisione e l'affidabilità del processo produttivo.

Quali trattamenti successivi alla lavorazione sono utili per migliorare le prestazioni?

Trattamenti come la lucidatura di precisione, i rivestimenti protettivi, l'indurimento delle superfici e il trattamento termico per l'eliminazione delle tensioni migliorano le prestazioni, la sicurezza e la durata dei componenti realizzati con macchine CNC.

Indice

- Fattori Chiave nella Valutazione della Qualità della Fresatura CNC

- Selezione dei Materiali per Componenti di Precisione

- Tecniche Avanzate di Misurazione per il Controllo Qualità

- Trattamenti Post-Lavorazione per Migliorare le Prestazioni

- Implementazione di Sistemi Continui di Controllo Qualità

-

Domande frequenti sui componenti di precisione per la lavorazione CNC

- Quali sono i principali fattori che influenzano la qualità dei componenti di precisione per la lavorazione CNC?

- Come la scelta del materiale impatta sulla lavorazione CNC?

- Quali sono i vantaggi dell'utilizzo di macchine a misurare tridimensionali (CMM) nella lavorazione CNC?

- Perché la rilevazione in tempo reale dei difetti è importante nella lavorazione CNC?

- Quali trattamenti successivi alla lavorazione sono utili per migliorare le prestazioni?