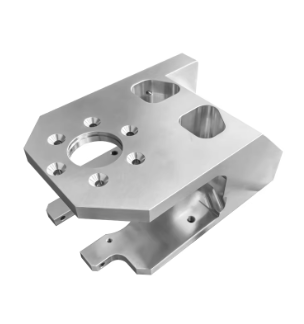

aluminum sheet metal fabrication

Aluminum sheet metal fabrication represents a sophisticated manufacturing process that transforms flat aluminum sheets into functional components through various techniques including cutting, forming, and assembly. This versatile process combines precision engineering with modern technology to create custom parts and products across multiple industries. The process begins with high-quality aluminum sheets, which undergo careful selection based on specific grade requirements and intended applications. Advanced CNC machinery, laser cutting systems, and precision brake presses work in concert to achieve exact specifications, ensuring dimensional accuracy and consistency in production. The fabrication process incorporates multiple stages, from initial design and prototyping to final assembly, with quality control measures implemented at each step. Modern aluminum sheet metal fabrication facilities utilize computer-aided design (CAD) software and automated systems to optimize production efficiency and maintain high standards of accuracy. This technology-driven approach enables manufacturers to produce complex geometries, intricate patterns, and precise components that meet stringent industry standards. The versatility of aluminum as a material, combined with advanced fabrication techniques, makes this process ideal for applications in aerospace, automotive, construction, and consumer goods industries, where lightweight, durable, and corrosion-resistant components are essential.