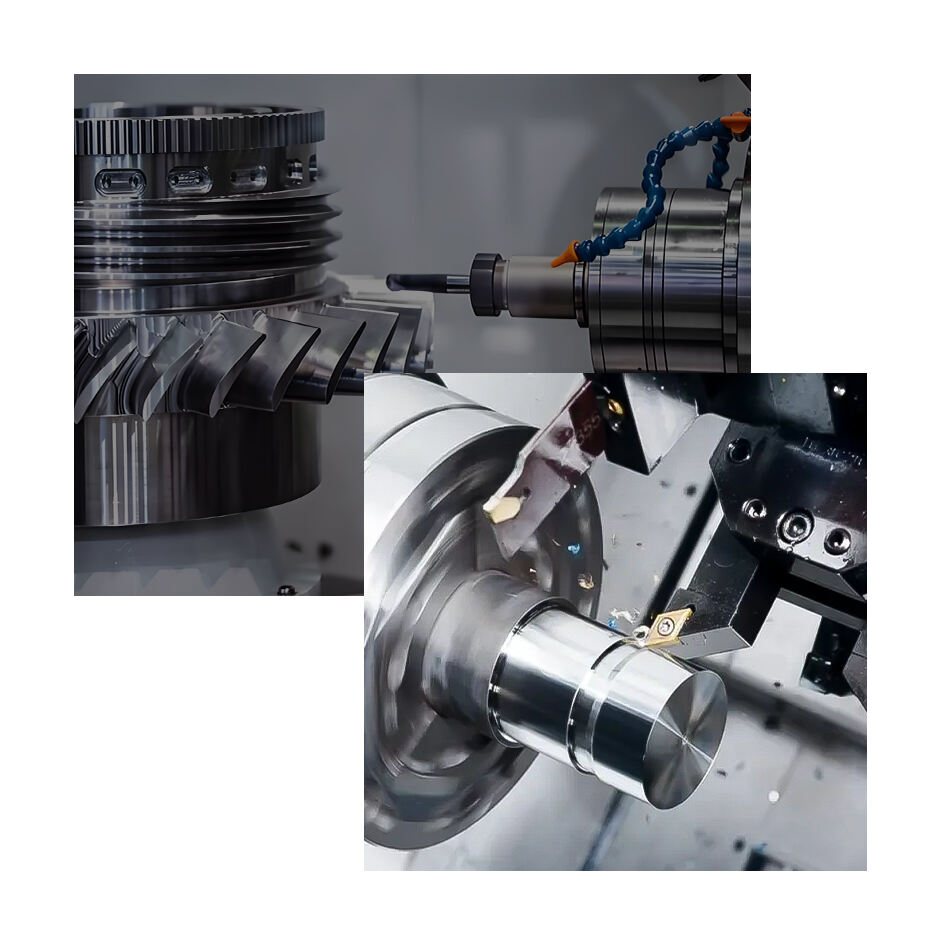

automation equipment parts manufacturer

Automation equipment parts manufacturers serve as crucial pillars in the modern industrial landscape, specializing in the production of high-precision components that form the backbone of automated systems. These manufacturers leverage cutting-edge technology and advanced manufacturing processes to create reliable, durable parts that meet the exacting standards of automation applications. Their product range encompasses everything from specialized sensors and actuators to complex control systems and mechanical components. Using state-of-the-art CNC machinery, 3D printing capabilities, and rigorous quality control protocols, these manufacturers ensure each component meets precise specifications. They employ advanced materials science and engineering principles to develop parts that can withstand demanding industrial environments while maintaining optimal performance. These facilities typically feature integrated design and production capabilities, allowing for rapid prototyping and custom solutions development. The manufacturing process incorporates smart factory principles, utilizing IoT sensors and real-time monitoring systems to maintain consistent quality standards. Their expertise extends to various sectors, including automotive manufacturing, electronics assembly, pharmaceutical production, and food processing industries, where automation plays a vital role in maintaining efficiency and consistency.