buy sheet metal parts

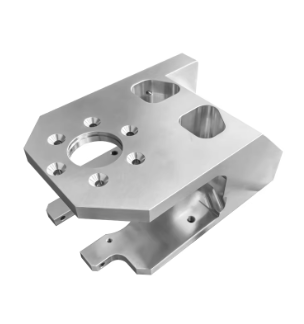

Buy sheet metal parts represents a crucial aspect of modern manufacturing and construction processes. These precision-engineered components are produced through various metalworking processes, including cutting, bending, and forming of metal sheets to create specific shapes and designs. Sheet metal parts are essential elements in numerous industries, from automotive and aerospace to electronics and construction. The manufacturing process typically involves advanced CNC machinery and skilled craftsmen who can transform raw metal sheets into complex components with tight tolerances and precise specifications. These parts can be manufactured using various materials such as steel, aluminum, copper, or brass, depending on the specific requirements of strength, durability, and cost-effectiveness. Modern sheet metal fabrication incorporates cutting-edge technology like laser cutting, stamping, and automated welding systems to ensure consistent quality and efficient production. The versatility of sheet metal parts allows for both small-scale custom projects and large-volume production runs, making them ideal for diverse applications across different sectors.