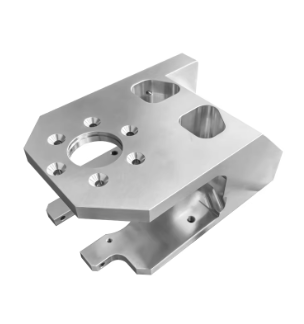

cnc precision machining parts factory

A CNC precision machining parts factory represents the pinnacle of modern manufacturing technology, combining advanced computerized control systems with high precision machinery to produce components with exceptional accuracy. These facilities utilize state of the art CNC machines, including multi axis milling centers, turning centers, and grinding equipment, capable of achieving tolerances as tight as ±0.001mm. The factory's operations are streamlined through automated processes, from digital design interpretation to final quality control inspection. Advanced CAD/CAM software systems enable the seamless translation of engineering designs into machining instructions, while sophisticated tool management systems ensure optimal cutting conditions. The facility specializes in processing various materials, including metals, plastics, and composites, producing components for industries such as aerospace, automotive, medical devices, and electronics. Quality control measures are implemented at every stage, utilizing coordinate measuring machines (CMM) and optical inspection systems to verify dimensional accuracy. The factory maintains climate controlled environments to ensure thermal stability during machining operations, crucial for maintaining precise tolerances. Modern CNC machining centers are equipped with automated tool changers and pallet systems, enabling 24/7 operation with minimal human intervention, thereby maximizing productivity while maintaining consistent quality.