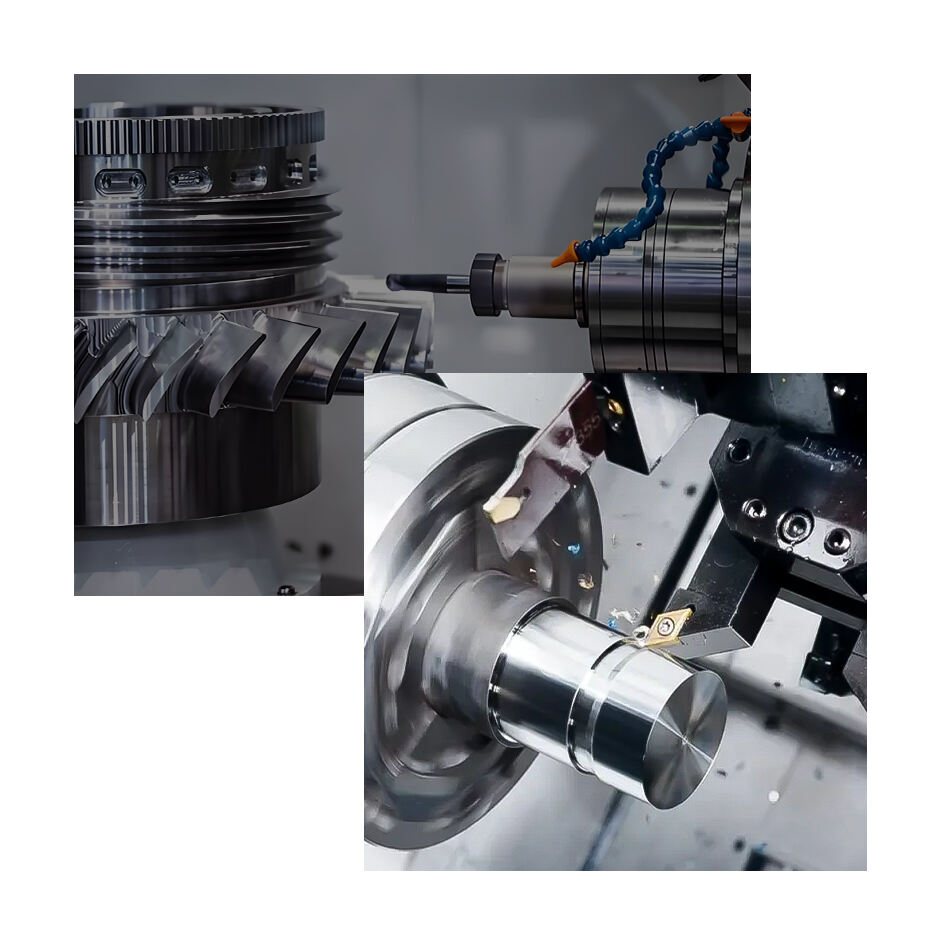

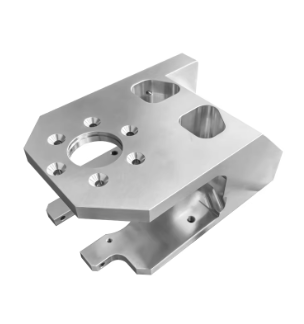

cnc precision parts

CNC precision parts represent the pinnacle of modern manufacturing technology, combining advanced computer numerical control systems with high-precision machining capabilities. These components are manufactured through automated processes that ensure exceptional accuracy, consistency, and quality in every production run. The manufacturing process involves sophisticated computer-controlled machinery that can execute complex cutting, milling, turning, and grinding operations with microscopic precision. These parts are essential in various industries, from aerospace and automotive to medical devices and electronics. The technology enables the production of components with tolerances as tight as ±0.001mm, ensuring perfect fit and functionality in assembly. CNC precision parts can be manufactured from a wide range of materials, including various metals, plastics, and composites, making them versatile for different applications. The automated nature of CNC machining not only guarantees consistency but also allows for rapid production of both prototype and production quantities. These parts often feature complex geometries, internal features, and intricate details that would be impossible to achieve through conventional manufacturing methods. The precision and reliability of CNC-manufactured parts make them crucial for high-performance applications where accuracy and dependability are paramount.