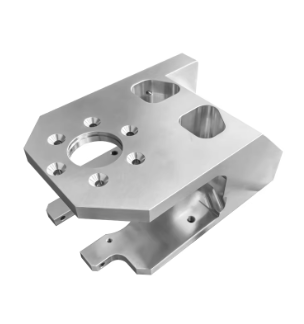

mechanical robot parts

Mechanical robot parts represent the fundamental building blocks of modern automated systems, comprising essential components such as actuators, sensors, controllers, end effectors, and structural elements. These sophisticated components work in harmony to enable precise movements, accurate sensing, and reliable operation in various industrial and commercial applications. The actuators serve as the muscles of the robot, converting energy into mechanical motion, while sensors act as the robot's nervous system, gathering crucial environmental data. Controllers function as the brain, processing information and coordinating movements, while end effectors are specialized tools designed for specific tasks. The structural components provide the necessary support and stability, ensuring smooth operation and durability. Advanced materials and precision engineering ensure these parts maintain optimal performance under various conditions, from high-speed assembly lines to delicate handling operations. Modern mechanical robot parts incorporate cutting-edge technologies such as smart sensors, adaptive control systems, and modular designs that facilitate easy maintenance and upgrades. These components are engineered to meet strict industry standards, offering reliability, precision, and longevity in demanding industrial environments.