semiconductor parts factory

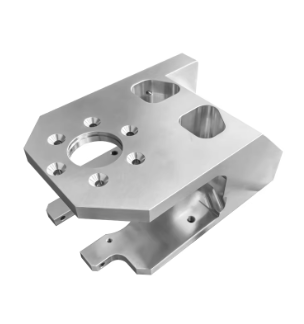

A semiconductor parts factory represents a cutting-edge manufacturing facility dedicated to producing essential components for electronic devices. These state-of-the-art facilities employ advanced manufacturing processes, including photolithography, etching, and ion implantation, to create microscopic circuits and components on silicon wafers. The factory operates in ultra-clean environments with controlled temperature, humidity, and particle levels to ensure product quality and reliability. Modern semiconductor facilities utilize automated material handling systems and robotic equipment to maintain precision and consistency throughout the production process. The factory's capabilities extend to producing various semiconductor components, including integrated circuits, transistors, and specialized chips for different applications. Quality control measures are implemented at every stage, from raw material inspection to final testing, ensuring each component meets strict industry standards. The facility integrates smart manufacturing principles, utilizing real-time data analytics and artificial intelligence to optimize production efficiency and yield rates. Environmental sustainability is also a key focus, with systems in place to minimize energy consumption and reduce waste. The factory serves diverse industries, including consumer electronics, automotive, telecommunications, and industrial automation, providing custom solutions to meet specific customer requirements.