semiconductor equipment parts manufacturer

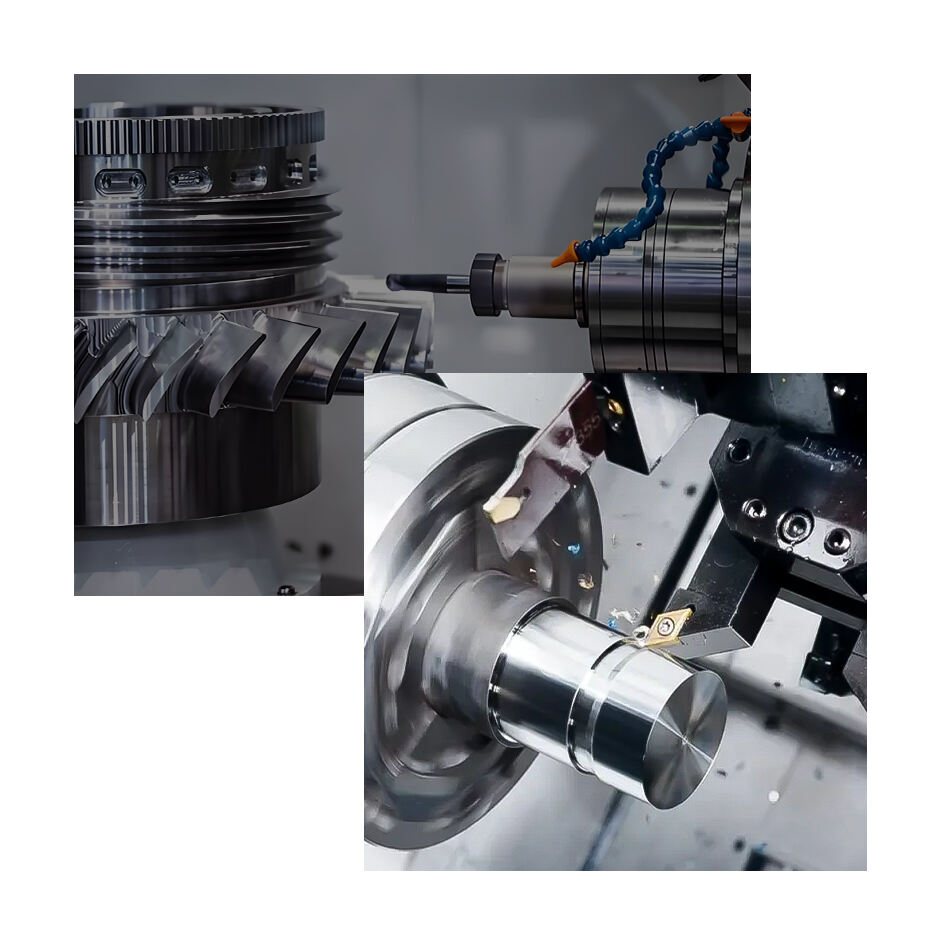

A semiconductor equipment parts manufacturer plays a crucial role in the modern electronics industry by producing high-precision components essential for semiconductor fabrication equipment. These specialized manufacturers employ advanced engineering processes and cutting-edge technology to create parts that meet the exacting standards required in semiconductor production. Their capabilities typically include precision machining, advanced materials processing, and sophisticated quality control systems. The manufacturer's facilities are equipped with state-of-the-art CNC machines, clean rooms, and testing equipment to ensure the production of components that meet strict industry specifications. They specialize in creating parts such as wafer handling systems, process chambers, gas delivery systems, and various mechanical and electrical components that are vital to semiconductor manufacturing equipment. The manufacturer's expertise extends to working with specialized materials including high-grade metals, ceramics, and advanced polymers that can withstand extreme temperatures and harsh chemical environments. Quality assurance processes are implemented at every production stage, from raw material selection to final testing, ensuring that each component meets or exceeds industry standards. These manufacturers also typically offer customization services, working closely with clients to develop specialized solutions for specific semiconductor manufacturing challenges.