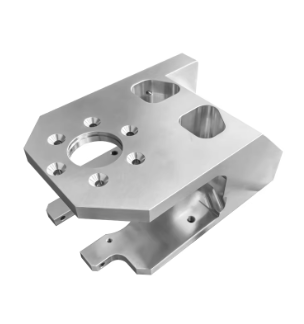

cnc machined plastic parts

CNC machined plastic parts represent a pinnacle of modern manufacturing precision, offering unparalleled accuracy and versatility in producing custom components. These parts are created through computer-controlled machining processes that transform raw plastic materials into precise, functional components. The technology employs sophisticated multi-axis CNC machines that can perform various operations including milling, drilling, turning, and threading with exceptional accuracy down to tolerances of +/- 0.001 inches. What sets CNC machined plastic parts apart is their ability to meet complex design requirements while maintaining consistent quality across production runs. These components can be manufactured from a wide range of engineering plastics, including PEEK, Delrin, PTFE, and UHMW, each selected based on specific application requirements such as chemical resistance, thermal stability, or mechanical strength. The versatility of CNC machining allows for the production of both prototype and production quantities, making it ideal for industries ranging from medical devices to aerospace applications. The process ensures superior surface finishes and the ability to create intricate features that would be impossible with traditional manufacturing methods.