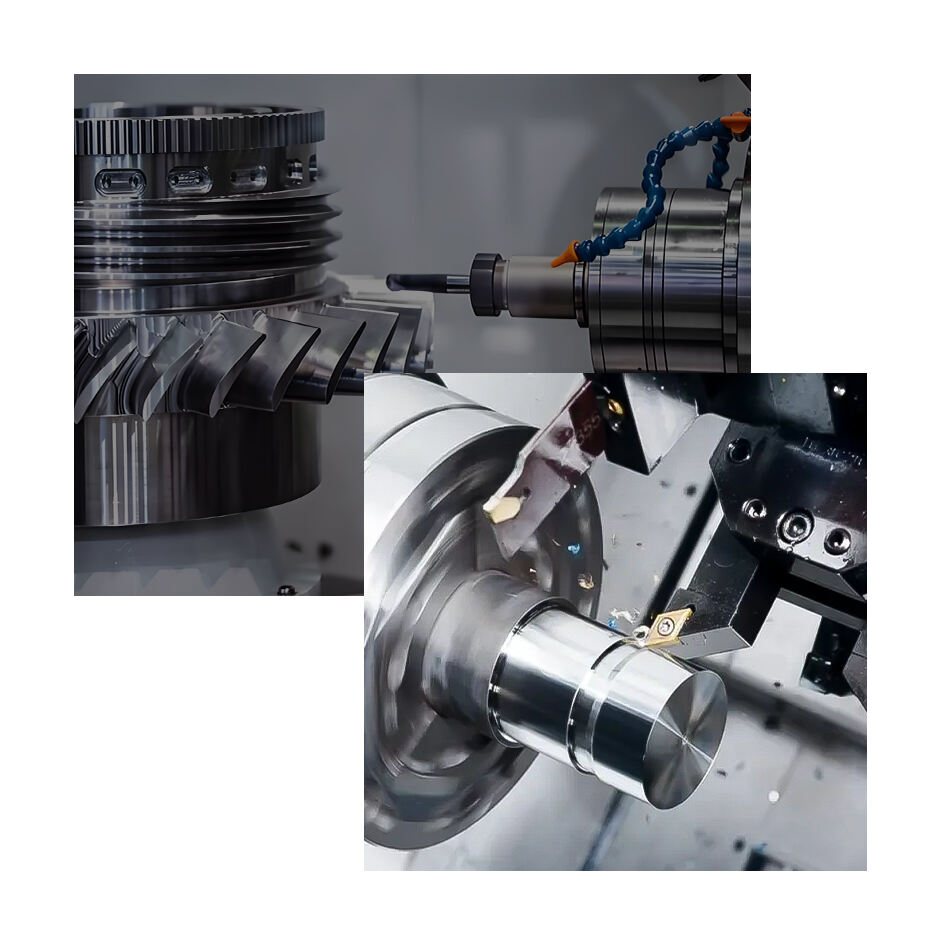

precision cnc machined components factory

A precision CNC machined components factory represents the pinnacle of modern manufacturing technology, combining advanced computer numerical control systems with high precision machinery to produce intricate parts with exceptional accuracy. These state of the art facilities utilize sophisticated multi axis CNC machines capable of achieving tolerances as tight as ±0.001mm. The factory's capabilities encompass a wide range of materials, including various metals, plastics, and composites, enabling the production of complex components for industries such as aerospace, automotive, medical devices, and electronics. The manufacturing process is entirely automated and computer controlled, ensuring consistent quality and reproducibility across production runs. Advanced quality control systems, including coordinate measuring machines (CMM) and optical inspection equipment, verify each component's dimensional accuracy. The factory maintains climate controlled conditions to prevent thermal expansion and contraction that could affect precision. Additionally, the facility employs skilled technicians and engineers who program and maintain the CNC machines, develop optimal machining strategies, and ensure quality standards are met throughout the production process.