precision cnc mill manufacturer

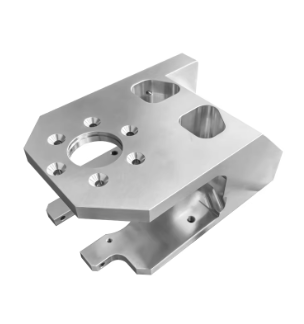

A precision CNC mill manufacturer represents the pinnacle of modern manufacturing technology, specializing in the design and production of high-precision computer numerical control milling machines. These sophisticated systems combine advanced mechanical engineering with cutting-edge digital control systems to deliver exceptional accuracy and reliability in manufacturing operations. The manufacturer integrates state-of-the-art features such as multi-axis capabilities, automated tool changing systems, and precision spindle technology to ensure optimal performance. Their machines typically offer positioning accuracy down to microns, enabling the production of complex components for industries ranging from aerospace to medical device manufacturing. The manufacturing facility implements rigorous quality control measures, utilizing advanced metrology equipment and testing protocols to maintain consistent product excellence. These manufacturers often provide comprehensive support services, including installation, training, and ongoing maintenance programs to ensure maximum machine uptime and productivity. Their commitment to innovation is reflected in continuous research and development efforts, resulting in regular updates to both hardware and software components to meet evolving industry demands.