semiconductor parts suppliers factory

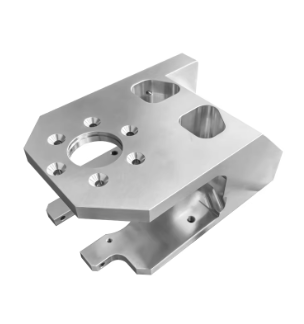

A semiconductor parts suppliers factory represents a critical link in the global electronics supply chain, serving as a specialized manufacturing facility dedicated to producing essential components for the semiconductor industry. These state-of-the-art facilities combine advanced manufacturing processes, precision engineering, and quality control systems to create reliable semiconductor parts that meet industry standards. The factory utilizes cutting-edge equipment and automated production lines to manufacture various components, including wafers, integrated circuits, and specialized electronic parts. Quality assurance protocols are implemented at every stage of production, from raw material inspection to final testing, ensuring consistent product performance and reliability. The facility maintains clean room environments with controlled temperature, humidity, and particle levels to prevent contamination during the manufacturing process. Advanced technical capabilities enable the production of components with nanometer-scale precision, meeting the demanding requirements of modern electronic devices. The factory's operations are supported by sophisticated inventory management systems and efficient logistics networks, ensuring timely delivery to customers worldwide. Research and development teams continuously work on improving manufacturing processes and developing new products to meet evolving market demands.