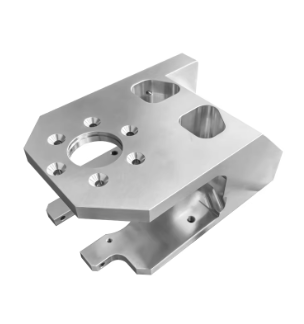

stainless steel parts

Stainless steel parts represent the cornerstone of modern industrial manufacturing, offering unparalleled durability and versatility across numerous applications. These precision-engineered components are crafted from high-grade stainless steel alloys, combining chromium, nickel, and other elements to create materials that resist corrosion, withstand extreme temperatures, and maintain structural integrity under demanding conditions. The manufacturing process involves advanced techniques including CNC machining, laser cutting, and precision forming, ensuring exceptional dimensional accuracy and surface finish. These parts find extensive use in industries ranging from aerospace and automotive to medical devices and food processing equipment. The inherent properties of stainless steel, including its high strength-to-weight ratio, excellent heat resistance, and superior hygiene characteristics, make these parts indispensable in critical applications. Modern stainless steel parts often incorporate innovative design features that optimize performance while minimizing material usage, resulting in cost-effective solutions without compromising quality. The adaptability of these components allows for customization to meet specific industry requirements, whether it's specialized fittings for pharmaceutical equipment or robust structural elements for architectural applications.